Functional Test

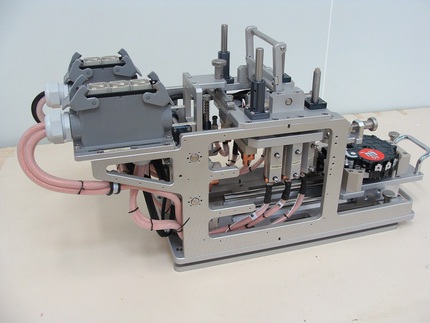

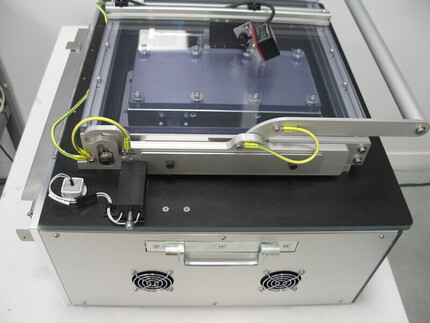

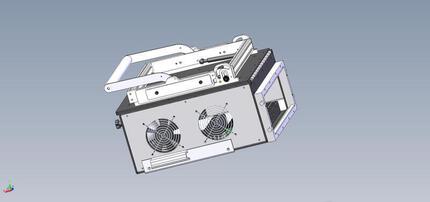

Pressure frame test fixture

We offter test fixtures with a mechanical system (pressure frame) enabling the test :

- Single face (top ou bottom).

- Double face (Top et Bottom).

- Connection on the sides of the product.

This simple, robust system is operated manually by the operator. However, the limitation of this mechanical principle works by the mechanical stresses caused by the number of test probes (<500).

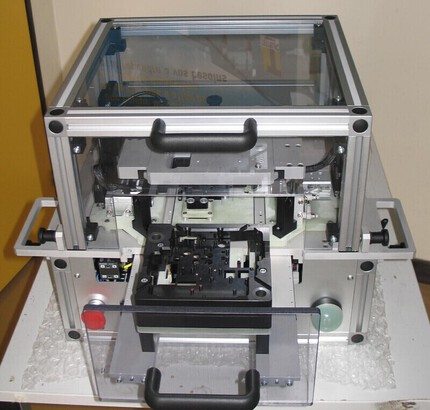

Interface à cadre presseur Testelec.

Interface à cadre presseur Testelec.

Interface à cadre presseur Testelec.

Interface à cadre presseur MA2111.

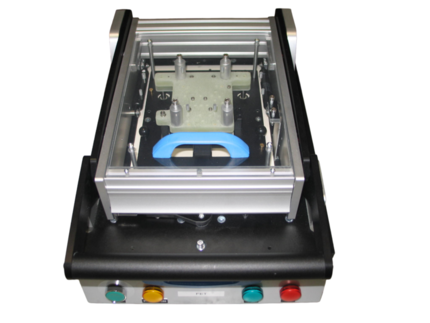

Interface MA2112 à cassette.

Interface à cadre presseur.

Interface de test pour détecteur CO2.

Interface à cadre presseur avec bandeau ODU.

Interface à cadre presseur avec bandeau ODU.

Interface de test à cadre presseur Testelec avec bandeau VPC 9025.

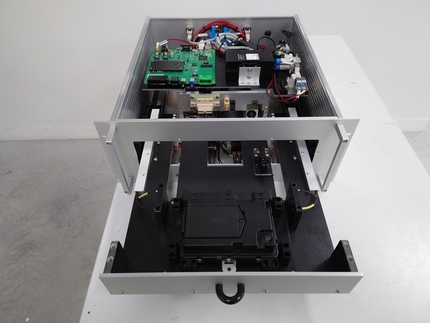

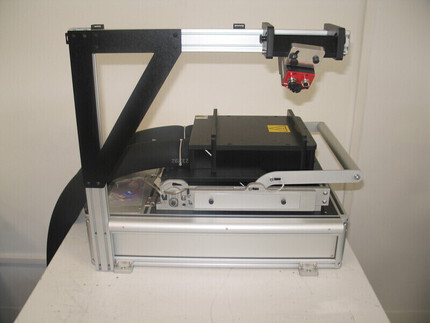

Automatic opening and/or closing test fixture

On this type of fixture the placement of the product is manual, the connection on the test chips and in the connectors is carried out automatically by pneumatic systems.

It is possible to connect automatically using Ethernet, Subb, USB AND all types of coaxial connectors with floating beds of nails.

It will also be possible to integrate control by optical sensors (LEDs, LCD, etc..) operated by pushbuttons with pressure and hardness controls.

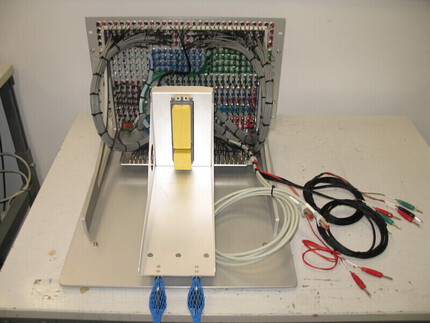

Manual test fixture

Testelec Ingénierie designs and produces test fixtures where the product is connected manually to connector counterparts or even beds of nails .

This type of test tool is used especially in a design office, in small batches or even in temperature testing.

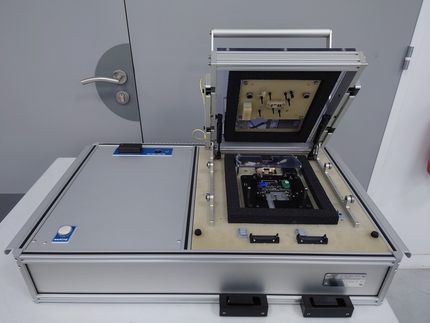

Dielectric test fixture

We develop dielectric test fixtures making it possible to perform high voltage tests (several KV).

Below are 2 examples of test fixtures for finished products in the medical and energy fields.

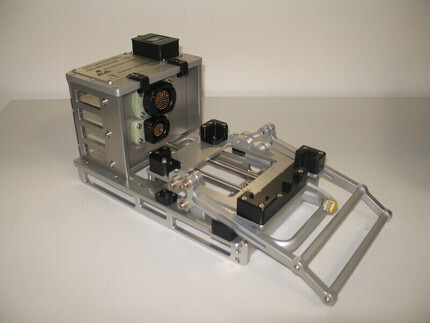

High temperature test fixture

We produce test fixture that can operate in a thermal chamber within the range of -50°C to +200°C as well as pressure frame fixtures incorporating a thermal box that can be connected to Temptronic or Froilabo air conditioners.